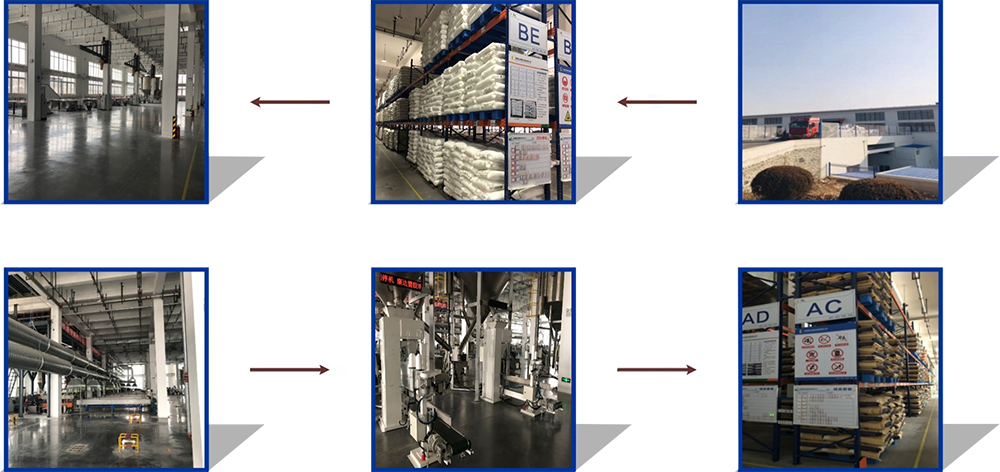

Production

Production system

Production area

20000 square meters

Production capacity

15 production lines

Annual capacity: 100,000 tons

Advanced equipment

Advanced professional production equipment such as twin screw extruder with high rotational speed and high torque and automatic weighing system.

Management system

Establish a perfect management system

ISO 9001:2015

IATF 16949:2016

ISO 14001:2015

OHSAS 18001:2007

Production process

Quality control ability

Incoming materials control

At present, most of the raw materials used by the company are products of well-known leading enterprises at home and abroad, such as Sinopec, PetroChina, SK, LG, Mitsui, Dow, Bayer, Shabick, etc. The company has established a supplier quality management system and signed strict quality assurance agreements with suppliers.

The company has established a complete raw material control process, and all raw materials are strictly inspected according to the《raw material inspection standards》 formulated by the Ministry of Technology before they are put into storage. At the same time, strict sample retention and batch management are implemented to ensure the traceability of raw materials.

Process control

《Quality Control Management Process of Production Process》

System management

Customer service

A full-time customer service team has been set up to track the whole process of order delivery, which provides a favorable guarantee for customer's product delivery.

Full-time Customer Service Engineer

Customer Service Response Time: Strictly specify the corresponding time according to the event level

Very urgent: within 5

hoursEmergency: within 24

hoursGeneral: within 72 hours